Product Description:

Aluminum Oxide Ceramic, also known as alumina ceramic, is a versatile material that offers exceptional properties suitable for a wide range of applications. This high-performance ceramic material is commonly used in industries such as electronics, aerospace, medical, and automotive due to its excellent mechanical and electrical properties.

One of the key attributes of Aluminum Oxide Ceramic is its Poisson's Ratio of 0.25, which indicates its ability to withstand deformation under stress. This makes it an ideal choice for applications that require high strength and stability.

Aluminum Oxide Ceramic, also referred to as alumina ceramic, is a popular choice for various components and substrates due to its exceptional dielectric strength of 18-20 KV/mm. This property makes it an excellent insulating material for electronic components, ensuring reliable performance in demanding environments.

When it comes to mechanical properties, Aluminum Oxide Ceramic stands out with its impressive flexural strength of 200-400 MPa. This high flexural strength makes it suitable for applications where resistance to bending and breaking is crucial, such as in structural components and high-wear environments.

The density of Aluminum Oxide Ceramic ranges from 3.75-3.9g/cm3, making it a lightweight yet durable material for a variety of applications. This optimal density ensures a balance between strength and weight, making it an ideal choice for components where weight reduction is a priority.

Aluminum Oxide Ceramic is often used as an alumina ceramic substrate, offering a reliable and stable platform for various electronic and mechanical components. Its high dielectric strength and excellent thermal properties make it a preferred choice for applications requiring precision and reliability.

For projects requiring a 99% Alumina ceramic plate, Aluminum Oxide Ceramic is the ideal material due to its purity and superior properties. The high alumina content ensures exceptional performance in terms of electrical insulation, thermal stability, and mechanical strength, making it a top choice for critical applications.

In summary, Aluminum Oxide Ceramic, or alumina ceramic, is a high-performance material that offers exceptional mechanical, electrical, and thermal properties. With its impressive Poisson's Ratio, dielectric strength, flexural strength, and optimal density, it is a versatile material suitable for a wide range of applications. Whether used as an alumina ceramic substrate or a 99% Alumina ceramic plate, Aluminum Oxide Ceramic delivers reliability, performance, and durability for various industries and applications.

Features:

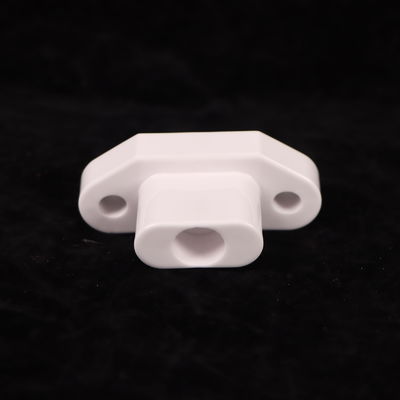

- Product Name: Aluminum Oxide Ceramic

- Thermal Conductivity: 25-35 W/mK

- Poisson's Ratio: 0.25

- Young's Modulus: 200-400 GPa

- Color: White

- Compressive Strength: >3000 MPa

Technical Parameters:

| Dielectric Constant |

9.6 |

| Poisson's Ratio |

0.25 |

| Thermal Expansion |

8.9 x 10^-6/K |

| Breakdown Voltage |

>20 KV |

| Flexural Strength |

200-400 MPa |

| Dielectric Strength |

18-20 KV/mm |

| Insulation Resistance |

>10^12 Ohm-cm |

| Tensile Strength |

200-400 MPa |

| Material |

Aluminum Oxide Ceramic |

| Hardness |

9 Mohs |

Applications:

The KAMTAI KT-YHL Aluminum Oxide Ceramic, with 95% Alumina content, is a versatile product suitable for various applications due to its exceptional properties. Here are the Product Application Occasions and Scenarios:

1. High Temperature Environments: The high temperature use alumina ceramic plate is ideal for applications where extreme heat resistance is required. It can withstand temperatures without compromising its structural integrity, making it perfect for use in furnaces, kilns, and other heat-intensive processes.

2. Electrical Insulation: With an Insulation Resistance of >10^12 Ohm-cm, this ceramic plate is well-suited for electrical insulation applications. It can be used in electrical components, insulators, and other devices where reliable insulation is crucial.

3. Mechanical Components: The KAMTAI KT-YHL Ceramic Plate's high hardness of 9 Mohs makes it suitable for use in mechanical components that require wear resistance and durability. It can be used in bearings, seals, cutting tools, and other high-wear applications.

4. Thermal Management: With a Thermal Conductivity of 25-35 W/mK, this ceramic plate is effective for thermal management applications. It can be used in heat sinks, thermal barriers, and other thermal control systems to efficiently dissipate heat.

5. Structural Applications: The 95% Alumina ceramic plate's Poisson's Ratio of 0.25 and density of 3.75-3.9g/cm3 make it suitable for structural applications where strength and stability are essential. It can be used in construction, aerospace, and other industries requiring reliable structural components.

Whether you need high temperature resistance, electrical insulation, mechanical strength, thermal conductivity, or structural stability, the KAMTAI KT-YHL Aluminum Oxide Ceramic Plate is a reliable choice. Place your order now with a Minimum Order Quantity of 300PCS. Price is negotiable, and the product is packaged securely in a wooden box for delivery. The supply ability is 500,000PCS per month, ensuring timely delivery within 30 days after payment. Certified with ISO 9001, this ceramic plate meets quality standards for various industrial applications.

Experience the exceptional performance and versatility of the KAMTAI KT-YHL Aluminum Oxide Ceramic Plate in your specific application scenarios.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!